DESCRIPTION

Aerofoil is specially designed for flow measurement in square/rectangular duct. This is particularly useful for duct, since the other flow elements like orifice, flow nozzle, etc. cannot be used for duct flow measurement. We are specialised & expert for aerofoil manufacturers.

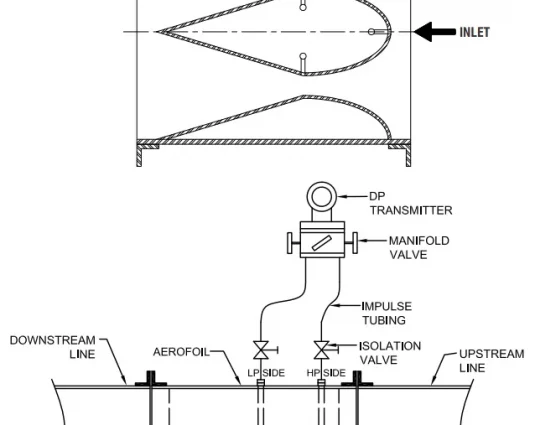

This consists of aerodynamic shaped foils, which offers a very little resistance to the fluid. The typical profile of Aerofoil, offers a smooth passage to the fluid which leads to the lesser pressure drop and thus more efficiency.

Aerofoil is supplied with flanged end, thus making the installation in the line, very easy.

MANUFACTURING RANGE

- A smallest aerofoil which we offer is of 500 x 500 mm size.

- For maximum side we can offer any dimension, as per the duct sizes.

MATERIALS

- Selection based on temperature and process conditions.

- Typically used materials is Carbon steel : IS 2061 Gr. A / B, SA516 Gr. 60/70.

SALIENT FEATURES

- Best suited for duct piping.

- Generally used in a low pressure area.

- Typical application of aerofoil is with air or gas application.

- Restricted for viscous fluids, since it will block the pressure sensing ports of the device.

- Zero maintenance since no moving parts.

- Less straight lengths requirement.

AEROFOIL

Aerofoil works on the principle of relationship between the flow velocity & the pressure fields in the flow section.

Consist of no. of foils, 02 nos. as a standard practice. The shape of each foil is similar to the shape of aircraft wing.

During operation, the fluid is passed between the foils, creating the pressure drop. Pressure sensing ports are placed on the face and backside to sense the upstream & downstream pressure, respectively.

These ports are connected to a two separate header pipe, which then gives out the upstream & downstream pressure. The difference between these gives input for flow rate calculation.

For designing of aerofoil, for rectangular duct, the dimensions are transformed into a similar circular section and performed the sizing. The results are re-transformed back to rectangular dimensions.

Size limits: 500 x 500 mm minimum Beta Ratio: 0.2 to 0.8

Pressure tapping: Throat taps.

Supplied with flanged end held in the line with fasteners. The flange drilling can be customized.