An averaging pitot tube (APT) is a multiport self-averaging flow meter with a design based on the classical Pitot tube concept of fluid flow measurement.

SALIENT FEATURES

- Averaging Pitot Tube is suitable for clean liquid, gas flow measurement

- Accuracy ± 2 % of actual flow rate

- Repeatability of measurement ± 0.2 %

- Flow rate turndown typically 4:1

- Short upstream and downstream straight pipe lengths

- Long term accuracy unaffected by wear

- Less pressure loss

MODEL SPECIFICATION

1) FEPT –75R with Ferrule Fitting construction. (Sensor size : 25.4 mm)

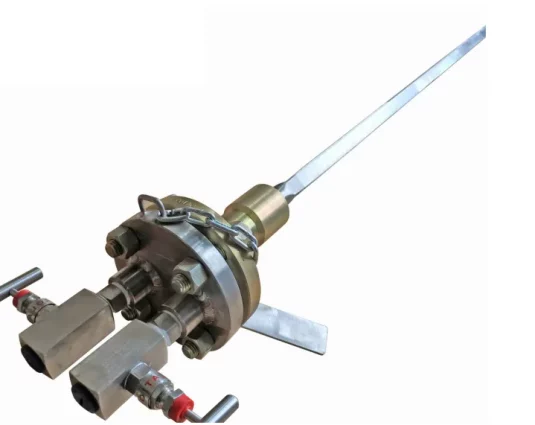

2) FEPT-75 with flanged construction (Sensor size 25.4mm)

3) FEPT-75/76 with Flanged construction & End support (Sensor size: 25.4 mm)

4) FEPT-85 with Flanged construction (Sensor size: 57.3 mm)

5) FEPT-86 with Flanged construction & End support (Sensor size: 57.3 mm)

APT models with flanged end can be supplied with retract mechanism, whenever specified.

Available retract mechanism are :

- Manual Retract mechanism

- Retract mechanism with gear drive

WORKING PRINCIPLE

Averaging Pitot Tube produces an averaged differential pressure (DP) proportional to the square of the flow rate. The DP output is normally piped to a Differential Pressure Transmitter in order to generate an electrical signal proportional to the flow rate.

For certain applications, the DP Transmitter can be directly mounted on to the APT via an integral 3-way valve manifold.

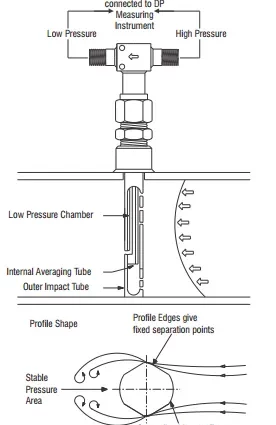

APT is designed to span the process pipe diameter and comprises four basic components:

- Outer impact tube

- Internal averaging tube

- Low-pressure chamber

- Head

The total pressures developed at each upstream hole by the impact of the flowing medium are firstly averaged within the outer impact tube and then to a second order (and more accurately) averaged within the internal averaging tube. This pressure is represented at the head as the high pressure component of the DP output.

The low-pressure component is generated from a single sensing hole located on the downstream side of the outer impact tube.

The outer impact tube has a number of pressure sensing holes facing upstream which are positioned at equal annular points in accordance with a log linear distribution.

APT is NOT suitable for the measurement of 2 phase fluids or when the fluid does not completely fill the cross section of the pipe.

PROFILE SHAPE

An APT has the unique diamond shaped profile enabling better separation point at which the flow lines “break-off” as the fluid passes around the outer impact tube. This feature creates a stable pressure area at the downstream pressure sensing hole thereby maintaining a more constant flow co-efficient K at high velocities enabling a very wide range of flow measurement (turndown).fluid which leads to the lesser pressure drop & thus more efficiency.

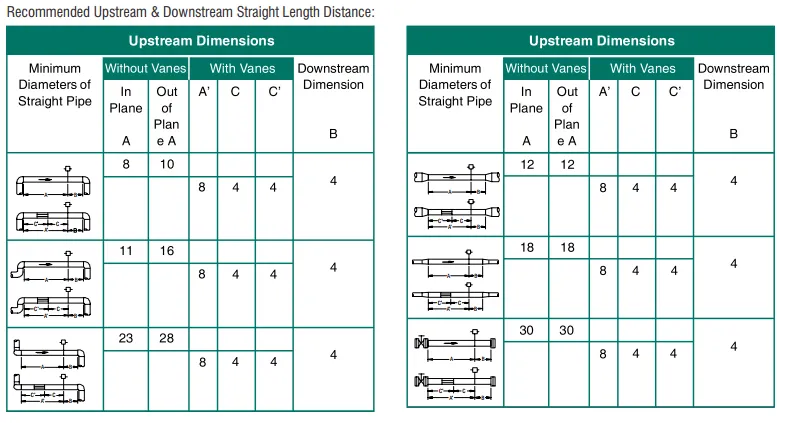

INSTALLATION & LOCATION

Correct location of averaging pitot tube in the pipe line system is important in order to optimize performance. Flow that is disturbed by upstream configuration such as elbows, T’s and valves may have an adverse effect on accuracy unless APT is located at recommended positions shown in below table.

Below figures illustrates the distance in multiples of pipe bore “D” between APT and the upstream and downstream disturbances. If an APT is fitted within disturbances less than those shown, then absolute

accuracy may be downgraded but repeatability of measurement will still be achieved due to inherent averaging characteristics.

Where it is not possible to provide the specified distances and maximum accuracy is required, the use of a flow straightening spool piece allows for shorter distance.